- โทรศัพท์: +86-18320991841

- อีเมล: sales@ljcpcbtech.com

- sales01@ljcpcbtech.com

PCB หลายชั้น

The Definition of Multilayer PCB

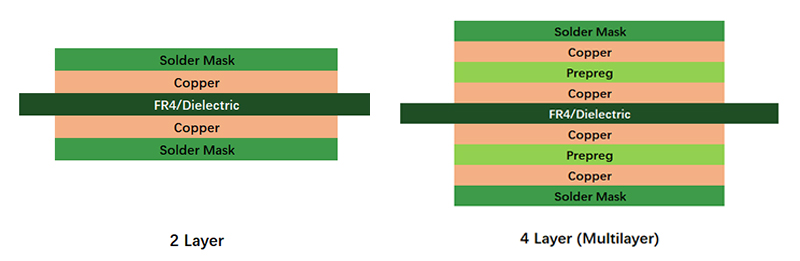

Compared with double-sided PCB or a 2-layer PCB board, Multi-Layer or Multilayer Printed Circuit Boards (พีซีบี), or Multilayer Boards (MLBs) must have a minimum of 3 conductive layers of conductive material or copper layer. All the layers are interconnected with copper plated holes, including NC vias and laser micro-vias either in plated through, or in buried and blind.

The Benefit of Multilayer PCB

Multilayer PCB can support a high level of circuit complexity because they consist of three or more copper layers laminated together.

Compact Size: Multilayer PCB reduces the overall size of electronic devices by combining multiple board functions into a single compact board.

Increased Component Density: With internal conductive layers and interlayer vias, multilayer PCB allows more components per unit area, enabling complex circuits to be realized in limited space.

Higher Reliability: Stronger bonds between laminated layers in multilayer PCB provides better resistance to temperature fluctuations, vibration, humidity and mechanical stress.

Improved Electrical Performance: Multilayer PCB provide dedicated signal, power, and ground planes for enhanced noise isolation, controlled impedance routing, and reduced EMI.

Enhanced Heat Dissipation: The planar layers in multilayer PCB can be patterned to efficiently direct heat away from critical areas for improved heat dissipation.

Easy Assembly / Testing: Integrating several simpler boards into a single multilayer PCB simplifies the assembly and testing process.

Design Flexibility: multilayer PCB allows for easier last-minute modifications by rewiring in the inner layers, providing greater flexibility than single or double-layer boards.

The Capability Overview of Multilayer PCB

| Item | Mass Production | Prototype | |

| Layer Count (Max) | 18 | 24 | |

| Board Material | High Frequency, Normal & High Tg FR4, IMS | High Frequency, Normal FR4, IMS, Hybrid Material | |

| Max. Copper Thickness | 6 OZ | 9 OZ | |

| Min. Core Dielectric Thickness | 0.0635 มม | 0.05 มม | |

| Layer to Layer Registration Tolerance | ±0.0635 mm | ±0.05 mm | |

| Finished Board Thickness | 0.4-5.0 มม | 0.35-5.0 มม | |

| Drilled Hole Size-Mechanical | 0.2-7.5 มม | 0.2-8.0 มม | |

| Min. Drilled Hole Size-Laser | 0.075 มม | 0.0635 มม | |

| Min. Buried Hole | 0.15 มม | 0.15 มม | |

| Press Fit Hole Tolerance | ±0.045 mm | ±0.04 mm | |

| Plated Through Hole Tolerance | ±0.0635 mm | ±0.05 mm | |

| Non-Plated Through Hole Tolerance | ±0.038 mm | ±0.025 mm | |

| BGA Pitch (with trace) | 0.45 มม | 0.4 มม | |

| Single-ended /Differential Impedance | ±8% | ±6% | |

| Min. Space Edge to Conductor | 0.175 มม | 0.15 มม | |

| Plating Aspect Ratio | 12:1 | 14:1 | |

| Minimum Line Width/Space (Inner Layer) | 1/2 oz Base Cu | 2.8/ 2.8 mil | 2.5 / 2.8 mil |

| 1 oz Base Cu | 3.2 / 3.8 mil | 3.0 / 3.5 mil | |

| 2 oz Base Cu | 5.2 / 5.6 mil | 4.8 / 5.2 mil | |

| 3 oz Base Cu | 6.5 / 8.0 mil | 6.2 / 7.5 mil | |

| 4 oz Base Cu | 8.6 / 10.2 mil | 8.2 / 9.8 mil | |

| 5 oz Base Cu | 10.0 / 11.5 mil | 9.5 / 11.0 mil | |

| Minimum Line Width/Space (Outer Layer) | 1/3 oz Base Cu | 2.8 / 3.0 mil | 2.5 / 2.8 mil |

| 1/2 oz Base Cu | 3.2 / 3.6 mil | 3.0 / 3.5 mil | |

| 1 oz Base Cu | 5.2 / 5.6 mil | 4.8 / 5.2 mil | |

| 2 oz Base Cu | 7.0 / 7.5 mil | 6.5 / 7.0 mil | |

| 3 oz Base Cu | 9.0 / 10.5 mil | 8.5 / 10.0 mil | |

| 4 oz Base Cu | 11.0 / 12.5 mil | 10.5 / 12.0 mil | |

| Solder Mask Registration | ±0.038 mm | ±0.025 mm | |

| Min. Solder Dam | 0.0635 มม | 0.06 มม | |

| Controlled Depth Drilling Tolerance | ±0.05 mm | ±0.05 mm | |

| Min. Delivery Panel Size | 60×75 มม | 60×60 มม | |

| Max. Delivery Panel Size | 520×600 มม | 520×650 มม | |

| Warpage Control | 0.45% max | 0.4% max | |

| Plated Over Filled Vias(POFV) | YES | YES | |

เซินเจิ้น Lianjincheng Precision Manufacturing Co., บจ.

เซินเจิ้น Lianjincheng Precision Manufacturing Co., บจ.